-

🏖️ Bel été à vous !

🏖️ Bel été à vous !Nous vous souhaitons de merveilleuses vacances ensoleillées 🌞 Notre équipe reste à votre écoute pour toute demande...

Lire la suite

-

Commandes d'été !

Chers clients,Avec l’arrivée des beaux jours, il est temps de penser aux indispensables de l’été ! Huiles corporelles satinées, soins...

Lire la suite

-

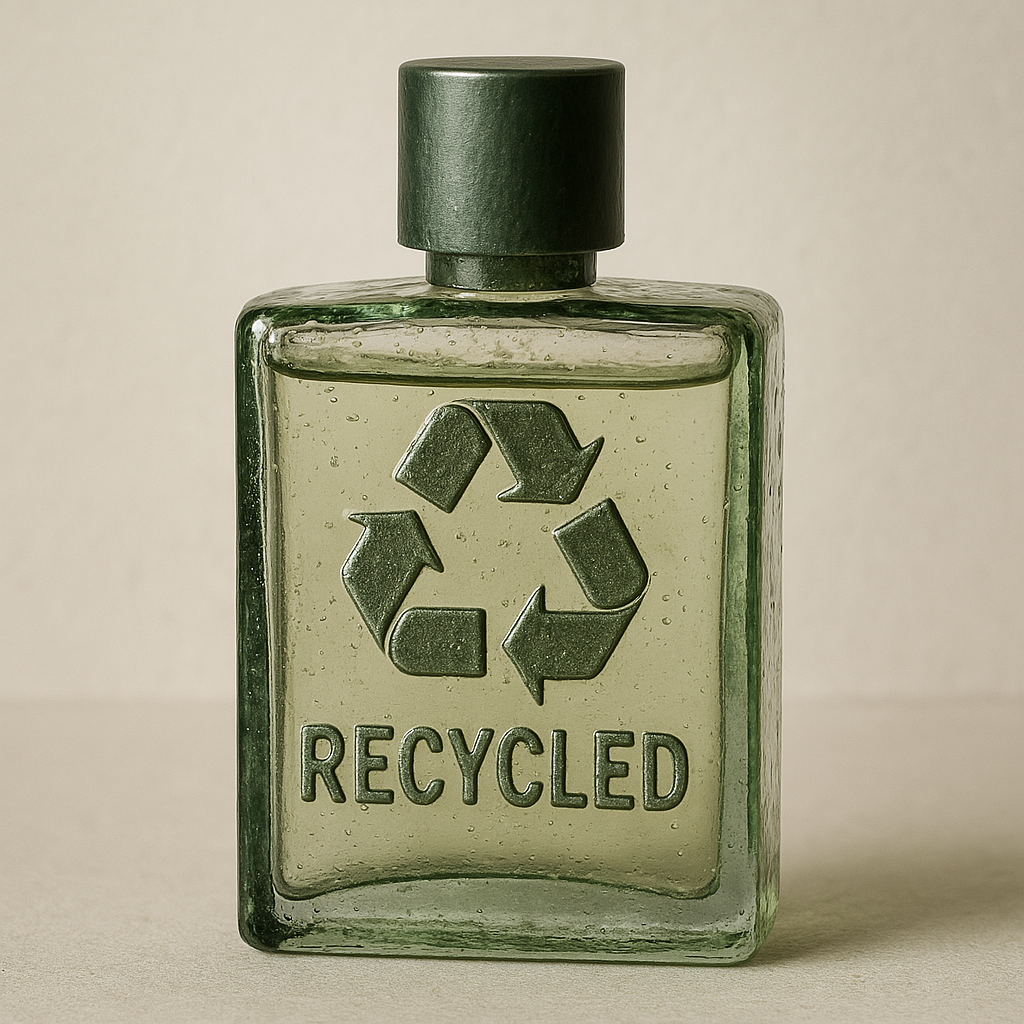

Des flacons recyclés !

🌿 Chez Satimat, le recyclage devient un art. ♻️Dans l’univers du parfum, chaque détail compte — jusque dans le flacon. C’est pourquoi...

Lire la suite

-

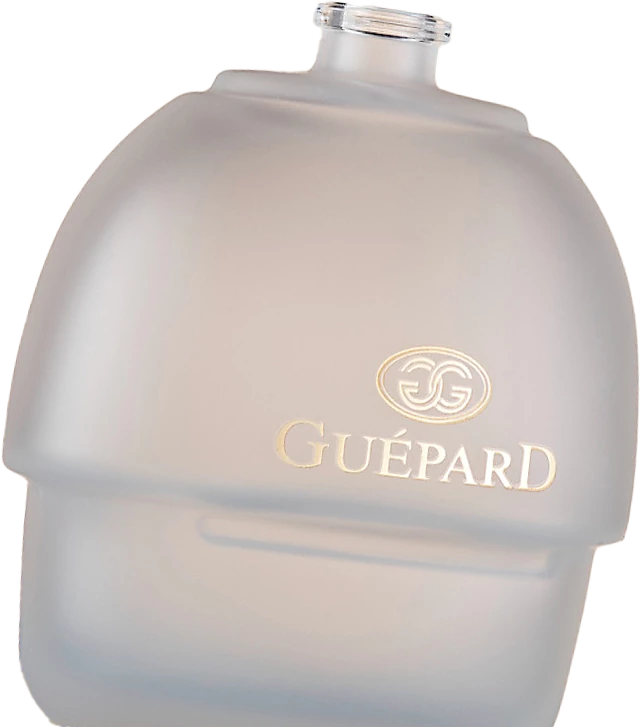

Dépolissage d'exception

✨ L’élégance en toute subtilité ✨Le verre dépoli est une véritable signature de raffinement. Son toucher velouté, son jeu de...

Lire la suite

-

Toute l'équipe de Satimat vous souhaite une bonne année 2025 !

Toute l'équipe de Satimat vous souhaite une bonne année 2025 !Pleine de bonheur, de joies, de travail, de business, toutes ses opportunités...

Lire la suite

-

Satimat vous souhaite de bonnes fêtes de fin d'année !

Exceptionnellement fermé du 23 Décembre 2024 au 3 Janvier 2025 Inclus, Satimat vous souhaite de bonnes fêtes de fin d'année! Les bureaux restent...

Lire la suite

-

L'hiver approche !

L'hiver approche, sortez les plaides et enclenchez le mode cocooning avec des bouteilles dépolies...

Lire la suite